Characteristics

The wide variety of applications that has been developed for aluminum and the sustained rise in consumption are due to a number of deciding factors when designers, manufacturers and users come to select their materials.

A unique combination of properties makes aluminum one of our most versatile engineering and construction material.

Aluminum's main characteristics are:

| light weight | The weight of aluminum is roughly 35% that of iron and 30% that of copper. |

|---|---|

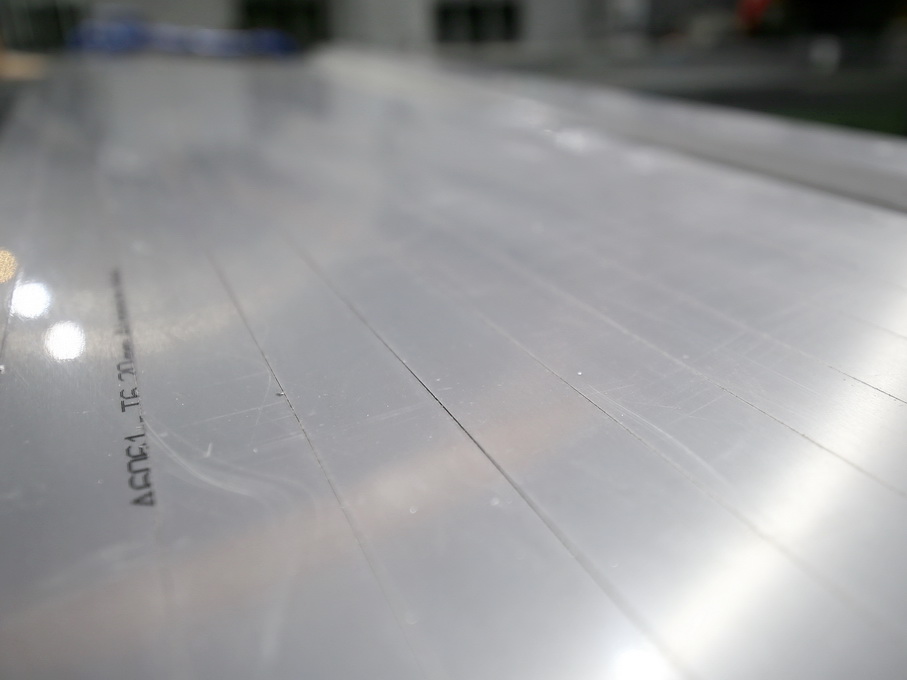

| High Corrosion Resistance | When aluminum surfaces are exposed to the atmosphere, a thin invisible oxide skin forms immediately, which protects the metal from further oxidation. It is also corrosion resistant to weathering and many other acids. |

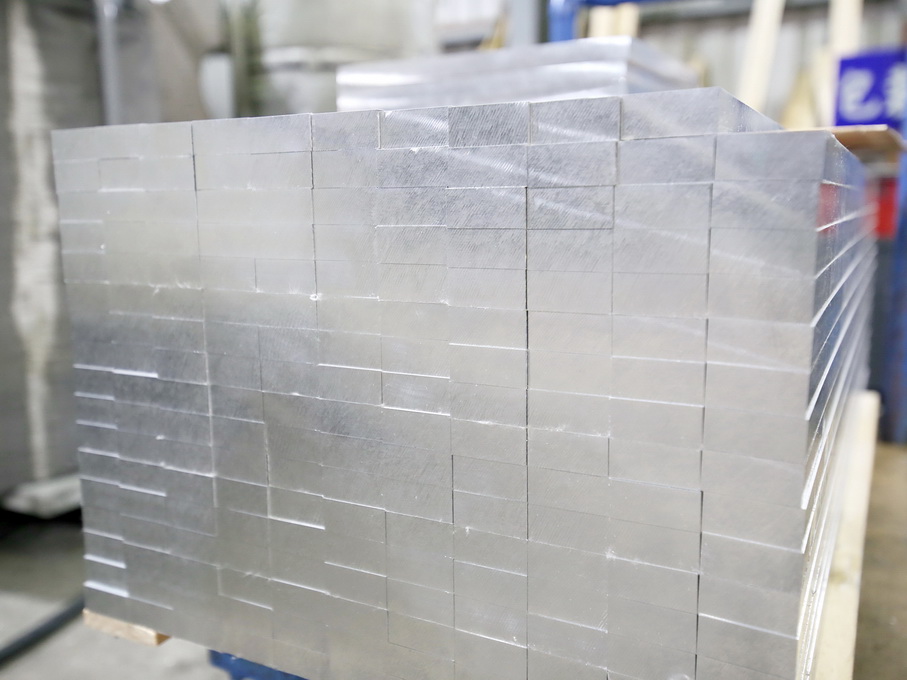

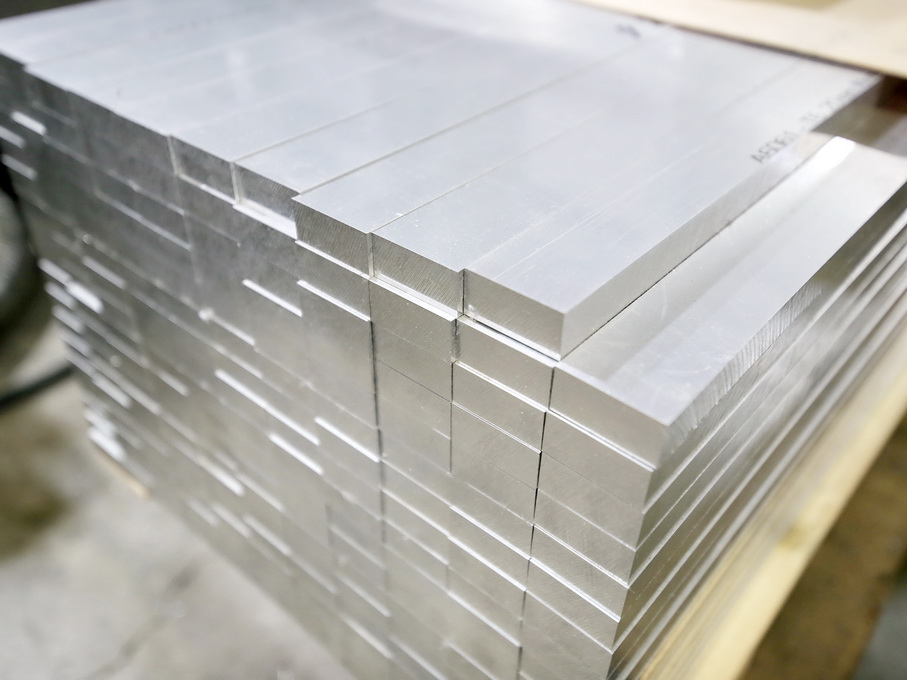

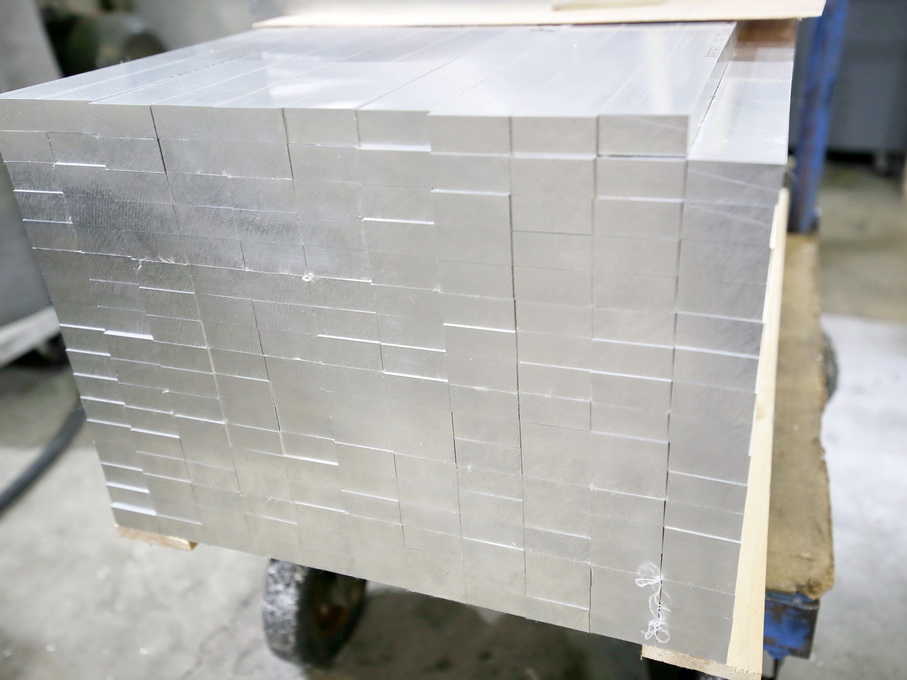

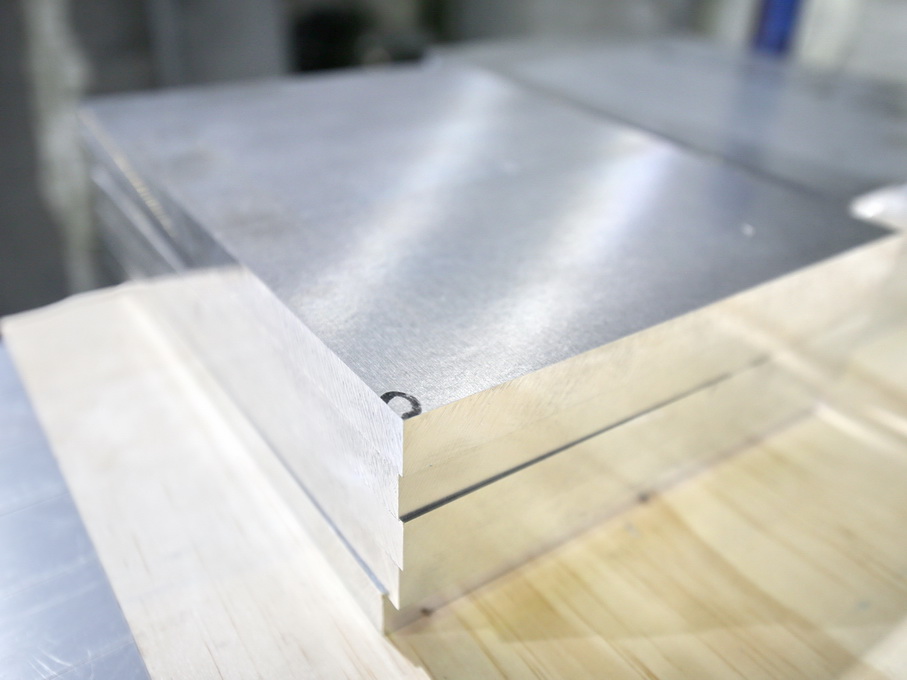

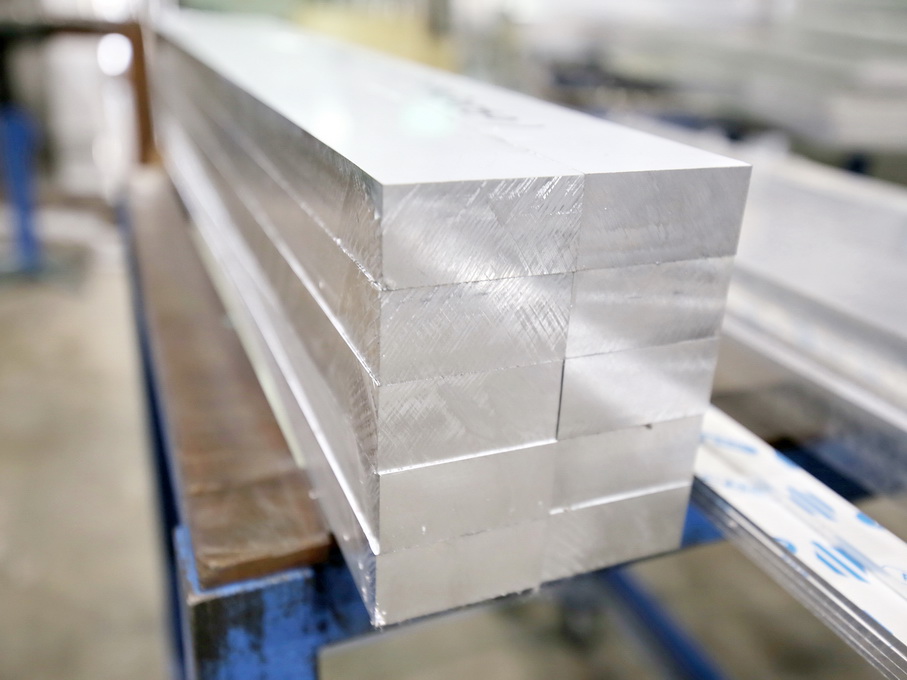

| Workability and excellent Formability | Aluminum can be processed to an almost infinite range of forms to meet various needs. The typical applications are aluminum wheels, ceiling lamp shade, capacitor shell and kitchen utensils. |

| Good Strength | By the addition of alloying elements and tempering, aluminum alloys are available in a variety of strengths. Strength may be selected to match product needs. Typical alloying elements are manganese, silicon, copper and magnesium. |

| Variety of Attractive Appearance | A wide range of finishes may be applied to aluminum to enhance its surface characteristics, or alter its appearance. The metallic surface may be colored by chemical or anodizing processes. Surface textures may be created, varying from rough to matte to mirror smooth. Coatings such as paint, lacquer, enamel, electroplating or laminate may also be applied. |

| Good Electrical Conductivity | The electrical conductivity of aluminum is around 62% of that of copper but it weights less than 1/3. This means that it conducts about twice as much electricity as copper of the same weight. Thus aluminum is in greater demand as conductors in numerous electrical applications. |

| Excellent Thermal Conductivity | Aluminum is an excellent conductor of heat, having around 60% of the thermal conductivity of copper, the optimum performer among common metals. This characteristic is important in heat-exchange applications (whether heating or cooling). Aluminum is used extensively in cooking utensils, air conditioning, industrial heat exchangers and automotive parts. |

| Variety of Forms | Aluminum can be easily fabricated into various forms, such as foil, sheet, geometric shapes, rod, tube and wire. |

| Machinability | Aluminum is much softer than steel and is easily to be machined satisfactorily. Aluminum displays excellent machinability and plasticity in bending, cutting and drawing. Generally speaking, alloy with higher strength has better machinability. |

| Weldability | Pure aluminium and Aluminum-Magnesium alloys are very suitable for welding. The typical uses are structural bodies and ship building. |

| Low Temperature Properties | At sub-zero temperatures, aluminum and its alloys increase in strength without loss of ductility or brittle fracture problems, so that aluminum is a particularly useful metal for low-temperature applications. |

| Non-toxic | Aluminum is non-toxic and is widely used in cooking utensils and today a great deal of aluminum equipment is used by food processing industries. Its non-toxic permits aluminum foil wrapping to be used safely in direct contact with food products. |

| Salvage | Aluminum recycling is a very attractive proposition both in the context of energy conservation and commercially. Aluminum scrap has a higher market value than steel scrap. It is one of the resources that can be reused efficiently on earth. |

| Non-Magnetic | Its non-magnetic properties make the metal useful for electrical shielding purposes such as in busbars or enclosures for other electrical or magnetic equipment. |

| Reflectivity | Aluminum has high reflectivity to visible light, radiation (heat) and electric waves. This feature is used for reflecting mirrors, reflectors (stoves, infra-red dryers, lighting), and wave guides. |